Managing a fleet is a high-stakes balancing act. Whether you oversee ten delivery vans or a hundred heavy-duty trucks, the goal remains the same: keep the wheels turning. When a vehicle goes down, the ripple effects are immediate. Deliveries get delayed, drivers are left stranded, and costs skyrocket. For years, fleet managers relied on whiteboards, spreadsheets, and sticky notes to track oil changes and tire rotations. But as logistics become more complex, manual tracking is no longer just inefficient—it is a liability.

The transition to digital solutions has revolutionized how companies approach vehicle health. By centralizing data and automating schedules, modern tools remove the guesswork from operations. This guide explores how implementing robust Fleet Maintenance Software can transform your business from a reactive fire-fighting operation into a proactive, data-driven machine.

The Hidden Costs of Reactive Maintenance

To understand the value of software, we first have to look at the problem it solves. Reactive maintenance—fixing things only when they break—is the most expensive way to run a fleet.

When a vehicle suffers an unexpected breakdown, you aren’t just paying for the tow truck and the emergency repair (which often comes at a premium rate). You are paying for the downtime. A truck sitting in the shop is a truck that isn’t generating revenue. Furthermore, unexpected delays can damage your reputation with clients who rely on punctuality.

There is also the administrative burden. Sifting through filing cabinets to find the last time a specific brake pad was replaced is a waste of valuable management time. Without a centralized system, warranty claims fall through the cracks, and parts inventory becomes a guessing game. This chaotic approach creates a ceiling on how much your business can grow.

Moving from Reactive to Proactive

The primary function of Fleet Maintenance Software is to shift your strategy from reactive to preventive. Instead of waiting for a failure, the system helps you anticipate needs before they become critical issues.

Automated Scheduling

The software acts as a centralized brain for your fleet. You can set triggers based on time, mileage, or engine hours. When a vehicle approaches a threshold—say, 5,000 miles since the last oil change—the system automatically flags it. This ensures that routine maintenance happens on schedule, extending the lifespan of your assets and preserving their resale value.

Streamlined Work Orders

Communication breakdowns between drivers, managers, and mechanics are common in manual systems. Digital platforms streamline this workflow. When a defect is reported, a work order can be generated instantly. Mechanics can see exactly what needs to be done, log the parts used, and close the ticket once the work is complete. This digital paper trail creates accountability and ensures that no repair request is ever lost in the shuffle.

Inventory Management

A disorganized parts room is a silent budget killer. Ordering parts you already have because you couldn’t find them, or waiting days for a critical component to arrive because you didn’t realize you were out of stock, slows down operations. Maintenance software tracks your inventory levels in real-time. It can tell you exactly how many oil filters you have on the shelf and alert you when supplies are running low, ensuring your shop is always ready to work.

The Power of Data-Driven Decisions

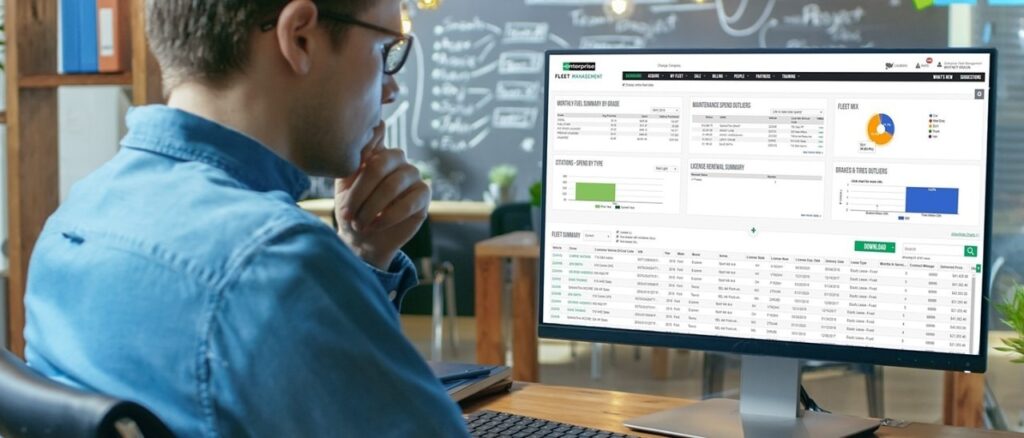

In the modern business landscape, data is your most valuable asset. However, raw data is useless if it isn’t organized and actionable. This is where Fleet Maintenance Software truly shines. It doesn’t just record what happened; it helps you understand why it happened.

By aggregating service history and cost data, the software allows you to run comprehensive reports. You can analyze the total cost of ownership for every vehicle in your fleet. You might discover that a specific make and model requires 30% more brake repairs than the rest of your fleet, or that older vehicles are costing more in repairs than their monthly replacement value.

These insights empower you to make smarter purchasing decisions. You can identify “lemon” vehicles early, decide when to retire aging assets, and accurately budget for future maintenance needs. Instead of guessing your budget based on last year’s spreadsheets, you can project costs based on real-time data trends.

enhancing Safety and Compliance

Beyond efficiency and cost, there is the critical issue of safety. Fleet managers have a moral and legal obligation to ensure their vehicles are safe for the road.

Fleet Maintenance Software creates a rigorous framework for safety compliance. It can digitize the Driver Vehicle Inspection Reports (DVIR). Instead of checking boxes on a piece of paper that might get lost in the cab, drivers can complete inspections via a mobile app. If they spot a cracked windshield or a bald tire, they can upload a photo and submit the report instantly.

This immediate reporting loop ensures that safety issues are addressed before the vehicle leaves the yard. Furthermore, having a complete, unalterable digital history of all inspections and repairs provides crucial documentation in the event of an audit or accident investigation. It proves that your company takes due diligence seriously.

Features That Define Top-Tier Solutions

Not all software is created equal. When evaluating potential solutions for your business, look for features that support flexibility and integration.

- Cloud-Based Accessibility: Your fleet is mobile, and your management system should be too. Cloud-based solutions allow managers to approve work orders from home and let drivers submit reports from the road.

- Mobile App Integration: The user interface for drivers and mechanics should be simple and mobile-friendly. If the software is difficult to use, your team won’t adopt it.

- Asset Tracking: The ability to track not just vehicles, but also heavy equipment, trailers, and other assets in a single dashboard.

- Integration Capabilities: The best systems can “talk” to your other business tools, such as GPS telematics or accounting software, creating a unified ecosystem of data.

Investing in Your Fleet’s Future

Adopting new technology requires a shift in mindset. It involves moving away from “the way we’ve always done it” and embracing a more structured, analytical approach. While there is an initial investment of time and resources to get set up, the return on investment is often realized quickly through reduced downtime and lower administrative costs.

Your vehicles are the heartbeat of your operation. Keeping them healthy shouldn’t be a source of stress. By leveraging the power of Fleet Maintenance Software, you gain control over your operations. You stop reacting to disasters and start planning for success, ensuring that your fleet—and your business—keeps moving forward efficiently.